Product Intro

LPL

Low Pressure Melamine Laminate

LPL is an eco-friendly surface finishing material that is impregnated and dried with melamine and urea resin on shape paper printed with various patterns and it can be self-attached to the MDF (Medium-density Fiberboard), PB (Particle Board) and HDF (High-density Fiberboard), etc. without harmful adhesives such as industrial glue.

Advantages

- Optimum finishing material with outstanding expressiveness and natural feeling, and blocked with harmfulness

- Price competitiveness compared to other surface finishing materials

- Outstanding surface properties such as powerful abrasion-resistance, scratch resistance, heat and water resistance, and chemical resistance.

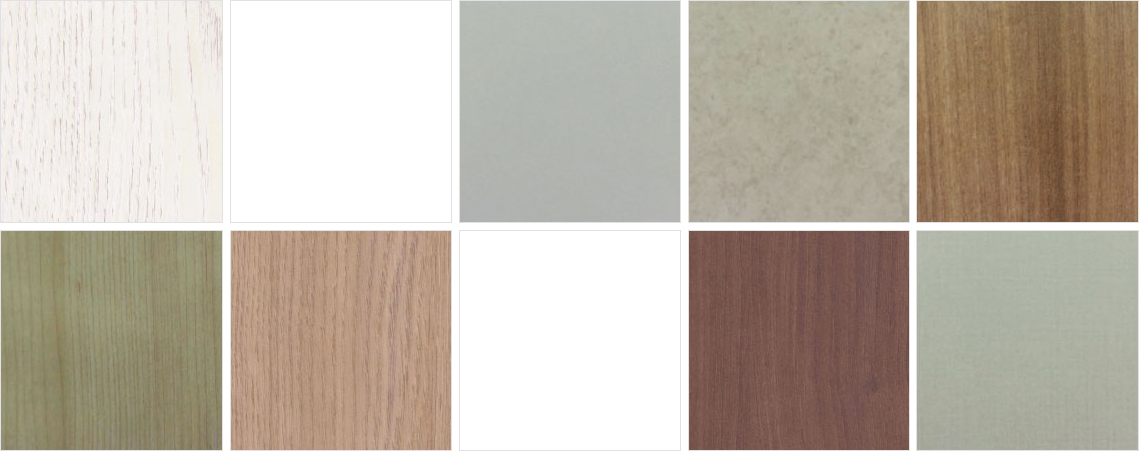

- Outstanding expressiveness such as semi-matte, matte, high-glossy (gloss) and emboss. (Reality)

- Adhesion method of using high-temperature hot pressing for excellent adhesiveness on the board

- Non-toxic (non-toxic, and harmful ingredients not detected on combustion)

- Eco-friendly than any other finishing materials through prevention on the spread of formalin and the emission of harmful formalin from the BOARD, etc.

- Various pattern printing possible (marble, fabric, wood, solid, abstract design, etc.)

- Independent R&D and design center for development and release of latest design

Use

Surface finishing material for general furniture, kitchen furniture, office furniture, built-in closet, wooden windows & doors, floor, wall panel and other interior furnitures

FF

Finishing Foil

FF (Finishing Foil) is an eco-friendly surface finishing material that is impregnated with thermoplastic resin on the shape paper and coated with water-based lacquer on the surface.

Advantages

-

The product can be applied in surface manufacture for not only the plane, but also on the curved surface for 3D effect

-

Luminous intensity can be controlled in the coating, and the product can be customized according to the purpose of use.

-

(For matte, semi-matte, gloss and re-coating purposes (Coating possible after attaching the foil – Urethane, Poly, UV, etc.))

-

Smooth and warm texture close to hardwood

-

Almost no discoloration (Unfading Property)

-

Outstanding physical properties (water-resistance, pollution resistant, abrasion resistance and chemical resistance)

-

Outstanding cutting than coating paper and PVC

-

Excellent covering power, and almost no peeling

-

Eco-friendly material that replaces the PVC

-

The self-adhensive rear side is possible for use as an interior foil (Can be attached immediately).

-

No toxic gas (Hci) emission on combustion thanks to a non-toxic and orderless product

-

(Vinyl PVC has a relatively high possibility of releasing toxic gas.)

-

Environmentally harmful substances are not released on disposal thanks to spontaneous combustion.

-

Outstanding eco-friendliness and properties to prevent the sick house syndrome and new furniture syndrome

-

Useful as a finishing material for building interior and furniture

ALPHA LAY

Aluminum Oxide Powder Surface Spray & Impregnation Method

Alpha Lay is a high-elasticity surface finishing material that is performed with both surface spray and impregnation of the aluminum oxide powder through the scattering equipment on the existing LPM impregnation to maximize the surface reinforcement.

Advantages

-

High-durability and high-quality that greatly improved the scratch and abrasion ratio

-

Possible to manufacture it with up to abrasion-resistance grade of “AC6”

-

The cost is reduced because overlay paper for floor is not required.

-

Application amount can be adjusted precisely during manufacture.

-

Production is also possible in small quantity.

-

In the future, new substances such as pearl, titanium and hologram can be stabilized on the surface of the product for various new product developments.

ALPHA LAY

Aluminum Oxide Powder Surface Spray & Impregnation Method

Alpha Lay is a high-elasticity surface finishing material that is performed with both surface spray and impregnation of the aluminum oxide powder through the scattering equipment on the existing LPM impregnation to maximize the surface reinforcement.

Advantages

-

High-durability and high-quality that greatly improved the scratch and abrasion ratio

-

Possible to manufacture it with up to abrasion-resistance grade of “AC6”

-

The cost is reduced because overlay paper for floor is not required.

-

Application amount can be adjusted precisely during manufacture.

-

Production is also possible in small quantity.

-

In the future, new substances such as pearl, titanium and hologram can be stabilized on the surface of the product for various new product developments.